Problems manufacturers face

Manufacturers face a variety of challenges including cost pressures, global competition, increased regulation, digital transformation and Industry 4.0, and a shortage of skilled workers. To mitigate these issues and remain competitive in the marketplace, manufacturers can focus on increasing efficiency and productivity in the manufacturing process by implementing lean manufacturing principles such as Six Sigma and Kaizen. Additionally, companies can explore automation and other technologies that can help to reduce labor costs and increase productivity. Navigating regulations can be achieved by working with regulatory agencies to understand the requirements and develop a compliance plan. Leveraging technology and data management, such as automation, IoT, machine learning, and other advanced technologies can streamline operations, improve efficiency and flexibility, and increase competitiveness. Investing in training and development programs to upskill existing employees and attract new talent, offering competitive compensation and benefits packages, and flexible work arrangements can help to attract and retain skilled workers. Finally, manufacturers can also look into various forms of financing, such as invoice financing or asset-based lending, to ease cash flow and fund their growth plans.

Improving manufacturing process with IIoT

The integration of internet-connected devices and sensors into industrial systems and procedures is known as the Industrial Internet of Things (IIoT). The IIoT has the potential to dramatically increase productivity and efficiency in the industrial sector by delivering real-time data and insights that can be used to streamline procedures and make wise decisions. Applying predictive maintenance is one method for using the IIoT to improve manufacturing processes. Predictive maintenance is a method that gathers information from sensors on machinery and equipment using the IIoT to determine when maintenance is required before a breakdown occurs.

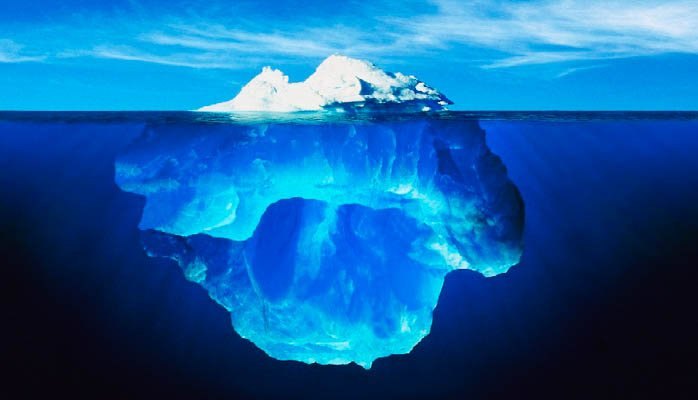

Problems Rise in manufacturing environment

According to industry experts, the most critical problem that can face any manufacturing environment through the production process is the cost of poor quality (COPQ) because of its direct effect on reducing the manufacturing process efficiency and that most of COPQ causes are hidden and not directly noticeable.

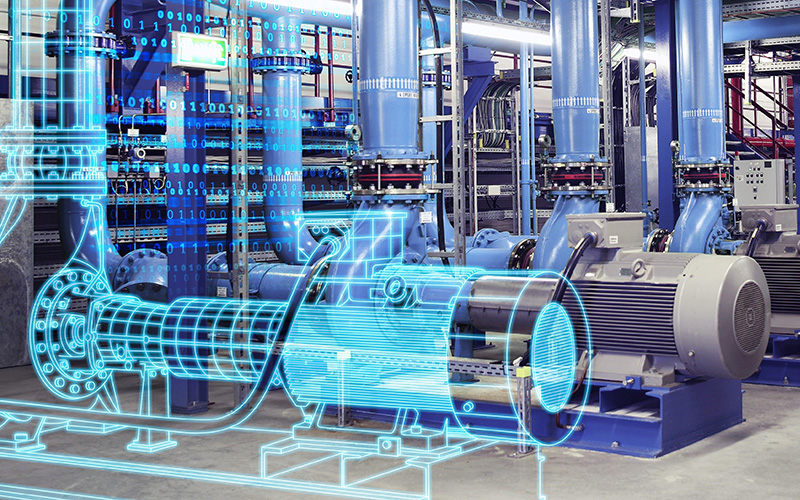

Digital Twin

Digital twin refers to a digital replica of physical assets, processes and systems that can be used for various purposes. The digital representation provides both the elements and the dynamics of how an IoT device, equipment, or machine operates and lives throughout its life cycle.

IIoT

The IIoT is part of a larger concept known as the Internet of Things (IoT). The IoT is a network of intelligent computers, devices, and objects that collect and share huge amounts of data. The collected data is sent to a central Cloud-based service where it is aggregated with other data and then shared with end users in a helpful way.

Data Science and Manufacturing

In a world where corporate executives have become accustomed to business analytics on demand, manufacturing remains a blind spot. The unique nature of manufacturing data makes it a big challenge to illuminate this blind spot.In a world where corporate executives have become accustomed to business analytics on demand, manufacturing remains a blind spot. The unique nature of manufacturing data makes it a big challenge to illuminate this blind spot.