Niotek Successfully Optimized on Intel Architecture

Niotek has successfully optimized its advanced Industrial IoT platform, HORUS, on Intel Architecture. HORUS, powered by AI, enhances manufacturing processes with features like hybrid architecture support, image classification, and asset failure prediction. Optimization using Intel's OpenVINO and Core Ultra processors delivers faster processing, lower latency, and high throughput. Niotek continues to innovate in IIoT and AI solutions, driving efficiency and reducing costs.

Predictive Maintenance: A Game-Changer for Industrial Efficiency

Learn how advanced technologies like the Industrial Internet of Things (IIoT) and machine learning are reshaping equipment upkeep, reliability, and operational efficiency.

How IIoT is Revolutionizing Manufacturing Processes

Explore how the Industrial Internet of Things (IIoT) is transforming manufacturing processes, ushering in a new era of efficiency, precision, and data-driven decision-making

Unleashing the Power of Connectivity in Industrial Operations

Explore Niotek's Industrial Internet of Things (IIoT) solutions, leading the way in connectivity, data-driven decision-making, and operational efficiency in the era of Industry 4.0.

Ensuring Security in Your Technology Tools: A Guide for Companies

In today's fast-paced digital landscape, technology plays a pivotal role in the success of any organization. From data storage and communication to project management and customer relations, technology tools are at the heart of business operations. However, with the increasing reliance on technology, ensuring that your technology tools are secure is paramount. In this blog post, we'll explore how companies can guarantee the security of their technology tools.

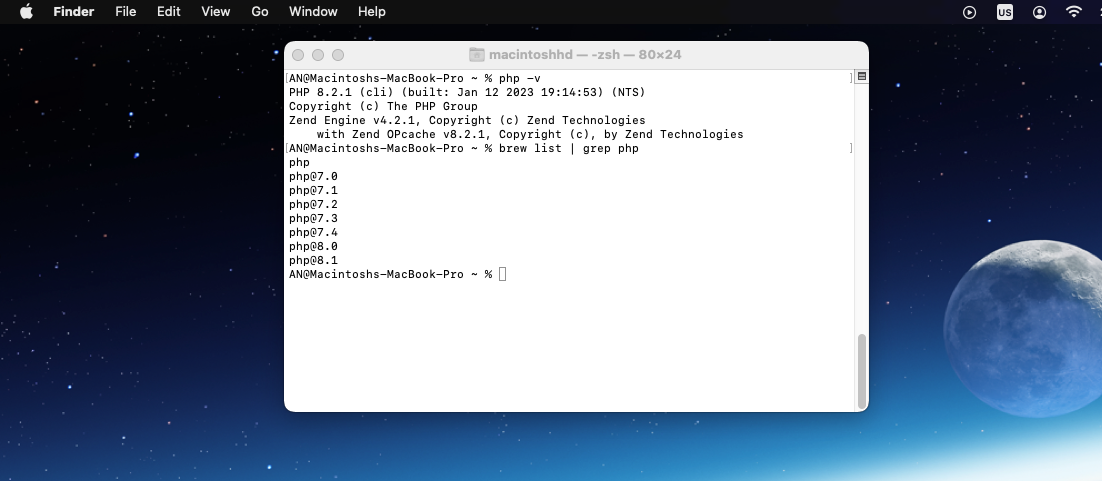

Installing multiple PHP versions on macOS

Most of us works on multiple projects of sub-products in the same time, so in this article I will cover how to install multiple PHP versions and how to switch between them. For PHP developers they may be using frameworks that require using a specific version of PHP, frameworks like Laravel have this issue as they do not focus on backward compatibility with old PHP versions, this can be a good practice to force you update your code.