Problems Rise in manufacturing environment

If you are in the field of manufacturing whether you in small, medium or even large enterprise then you may have heard or faced multiple problems related to production environment.

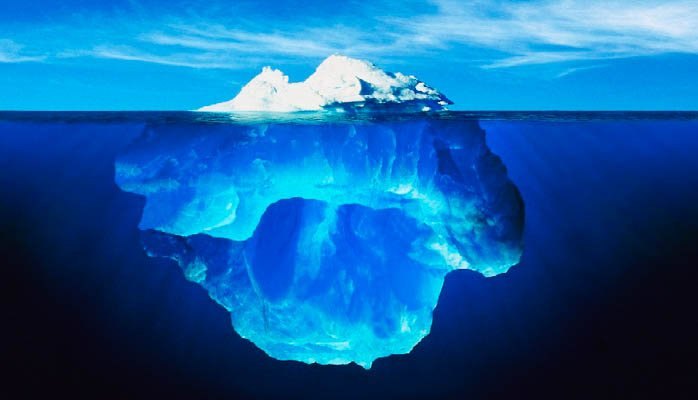

All these problems you know about are good for you and your production environment as it makes you enhance and improve the process, but on the other hand In most of cases it is not that easy!, there is a hidden part of your problems that you cannot catch or identify and in best situations you feel that there is something going wrong.

In this article we will focus on problems you cannot catch or identify and how we can help you do this.

Most of us may heard about the titanic ship and the iceberg, well you may have and iceberg facing your business or job without even seeing it! This iceberg is the cost of poor quality.

According to industry experts, the most critical problem that can face any manufacturing environment through the production process is the cost of poor quality (COPQ) because of its direct effect on reducing the manufacturing process efficiency and that most of COPQ causes are hidden and not directly noticeable.

Total Cost of quality

Before diving in deep in cost of poor quality lets know what are the two types of costs related to quality? There is:

- Cost of good quality.

- Cost of poor quality.

Cost of good quality (COQ) is defined as a methodology that allows an organization to determine the extent to which its resources are used for activities that prevent poor quality, that appraise the quality of the organization’s products or services, and that result from internal and external failures.

On the other hand Cost of poor quality (COPQ) is defined as the costs associated with providing poor quality products or services.Cost of good Quality

The costs of good quality are broadly broken down into prevention costs and appraisal costs.

Prevention costs

Prevention costs are incurred to prevent or avoid quality problems. These costs are associated with the design, implementation, and maintenance of the quality management system. They are planned and incurred before actual operation, and they could include:

- Process control: controlling the manufacturing process activities and following it.

- Product or service requirements: establishment of specifications for incoming materials, processes, finished products, and services

- Quality planning: creation of plans for quality, reliability, operations, production, and inspection

- Quality assurance: creation and maintenance of the quality system

- Quality management and programs

- Design reviews: the cost of reviewing and testing the products.

- Training: development, preparation, and maintenance of programs

Appraisal costs

Appraisal costs are associated with measuring and monitoring activities related to quality. These costs are associated with the suppliers’ and customers’ evaluation of purchased materials, processes, products, and services to ensure that they conform to specifications. They could include:

- Verification: checking of incoming material, process setup, and products against agreed specifications

- Quality audits: confirmation that the quality system is functioning correctly

- Supplier rating: assessment and approval of suppliers of products and services

Cost of Poor Quality

Internal failure costs

Internal failure costs are incurred to remedy defects discovered before the product or service is delivered to the customer. These costs occur when the results of work fail to reach design quality standards and are detected before they are transferred to the customer. They could include:

- Waste: performance of unnecessary work or holding of stock as a result of errors, poor organization, or communication

- Scrap: defective product or material that cannot be repaired, used, or sold

- Rework or rectification: correction of defective material or errors

- Failure analysis: activity required to establish the causes of internal product or service failure

- Productivity costs.

- Material replacement costs.

External failure costs

External failure costs are incurred to remedy defects discovered by customers. These costs occur when products or services that fail to reach design quality standards are not detected until after transfer to the customer. They could include:

- Repairs and servicing: of both returned products and those in the field.

- Warranty claims: failed products that are replaced or services that are re-performed under a guarantee. Complaints: all work and costs associated with handling and servicing customers’ complaints.

- Returns: handling and investigation of rejected or recalled products, including transport costs.

- Regulatory fines and penalties.

- Less tangible costs like brand damage and loss of customers

COPQ can lead directly to multiple issues for example:

Conclusion

Every business have both types of quality related costs and your target is to do and the cost a quality job, conducting quality improvements, and achieving goals must be carefully managed so that the long-term effect of quality on the organization is a desirable one.

The role of quality related costs are obvious especially in manufacturing process as it affects production, supply chain, customer relationship and the whole business aspects.