Improving manufacturing process with IIoT

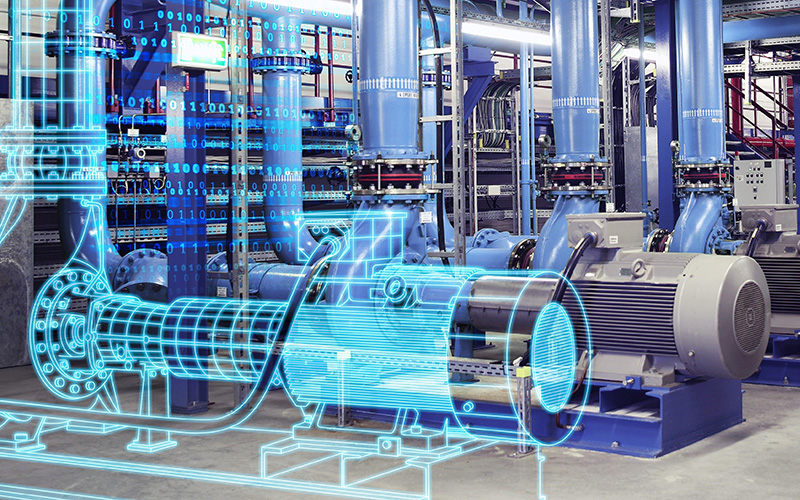

The integration of internet-connected devices and sensors into industrial systems and procedures is known as the Industrial Internet of Things (IIoT). The IIoT has the potential to dramatically increase productivity and efficiency in the industrial sector by delivering real-time data and insights that can be used to streamline procedures and make wise decisions.

Forget the factory floors of yesterday. The Industrial Internet of Things (IIoT) is reshaping manufacturing, unlocking game-changing boosts in productivity and efficiency. Imagine a world where industrial devices and sensors chat with the internet, generating a treasure trove of real-time data and insights. That's the IIoT, empowering smarter decisions and streamlined operations for savvy manufacturers.

Predictive Maintenance: Downtime? Not on Our Watch!

One key IIoT weapon? Predictive maintenance. Applying predictive maintenance is one method for using the IIoT to improve manufacturing processes. Predictive maintenance is a method that gathers information from sensors on machinery and equipment using the IIoT to determine when maintenance is required before a breakdown occurs. This may result in a reduction in downtime and a longer equipment lifespan, enabling uninterrupted production. Manufacturers can also lessen the requirement for unscheduled maintenance, which can be time-consuming and disruptive to the production process, by using predictive maintenance.

Supply Chains? More Like Efficiency Chains!

The IIoT isn't just about machines, it's about the whole ecosystem. The supply chain management process can be optimized as another approach to leverage the IIoT to enhance industrial processes. Real-time tracking of the flow of products through the supply chain allows manufacturers to see bottlenecks and inefficiencies and take remedial action. Through improved material flow and shortened lead times, this can boost productivity and efficiency. Additionally, real-time inventory management enables producers to spot shortages and surpluses as they arise, enabling them to take appropriate action and boost production efficiency.

Quality Control? It's Like Having a Hawk Eye on Your Process

Quality matters. And the IIoT helps you ensure it. The IIoT can also be utilized to improve manufacturing quality control. Manufacturers can detect flaws and violations from set criteria and take corrective action to enhance quality by collecting data on the production process in real-time. This can enhance customer satisfaction by lowering rework and scrap. The IIoT may also be used to track the functioning of machinery and equipment, enabling producers to see faults and fix them before they worsen.

Energy Efficiency? The IIoT Makes it a Green Dream

Going green isn't just good for the planet, it's good for your bottom line. The IIoT can also be implemented to help improving manufacturing's energy efficiency in addition to these advantages. Manufacturers can find opportunities for energy saving and put measures in place to lower consumption by gathering data on energy use. As a result, efficiency and production may grow and the bottom line may be improved.

The IIoT Advantage: It's All About Streamlining and Boosting

The IIoT isn't magic, but it might feel like it. It empowers manufacturers with a treasure trove of real-time data and insights, paving the way for significant efficiency and productivity gains. By implementing IIoT solutions, you can optimize predictive maintenance, streamline supply chains, ensure quality control, minimize downtime, and achieve greater energy efficiency. This holistic approach leads to a more competitive, sustainable, and profitable manufacturing operation. So, what are you waiting for? Embrace the IIoT revolution and watch your manufacturing soar!