Case Study: HORUS Implementation for Low Voltage Cables Industry

Project Overview:

Niotek successfully implemented HORUS on 24 machines for low voltage cables in a cutting-edge project that showcased impressive results within a short timeframe. The project, executed within a budget of 100,000 USD, aimed to revolutionize maintenance processes, reduce downtime, and integrate seamlessly with SAP ERP for enhanced traceability and key performance indicators (KPIs).

Challenges:

The low voltage cables industry faced challenges related to high maintenance costs, prolonged downtimes, and the need for improved traceability and performance metrics.

Solution:

HORUS, Niotek's advanced platform, was deployed to address these challenges by providing real-time monitoring, predictive maintenance capabilities, and integration with SAP ERP for comprehensive traceability and KPI monitoring.

Implementation Highlights:

- Maintenance Cost Reduction: The implementation led to a substantial 15% reduction in overall maintenance costs, achieved through predictive maintenance and real-time monitoring.

- Downtime Reduction: Downtime was reduced by an impressive 20%, ensuring continuous production and minimizing operational disruptions.

- Efficiency Gains: HORUS streamlined maintenance order creation, reducing the time from an average of 10 minutes to just 30 seconds, resulting in increased operational efficiency.

Integration with SAP ERP:

HORUS seamlessly integrated with SAP ERP, providing full traceability of production progress, material consumption, and feeding SAP ERP with vital KPIs such as availability, quality, performance, and Overall Equipment Efficiency (OEE).

Results:

Within two months of implementation, the project showcased remarkable results:

- Increased Productivity: The low voltage cables factory witnessed a significant increase in productivity by 40 Ton within two months.

- Enhanced Quality: The implementation of HORUS led to the discovery and resolution of issues causing waste in production and quality concerns, resulting in improved product quality.

- Operational Optimization: By focusing efforts on innovation and continuous development, the factory achieved savings that benefited both the economy and the environment.

Conclusion:

Niotek's implementation of HORUS for the low voltage cables industry exemplifies the platform's transformative impact. The project not only realized substantial cost savings and efficiency gains but also showcased the platform's versatility in seamlessly integrating with SAP ERP, providing a holistic solution for enhanced productivity, traceability, and overall operational excellence.

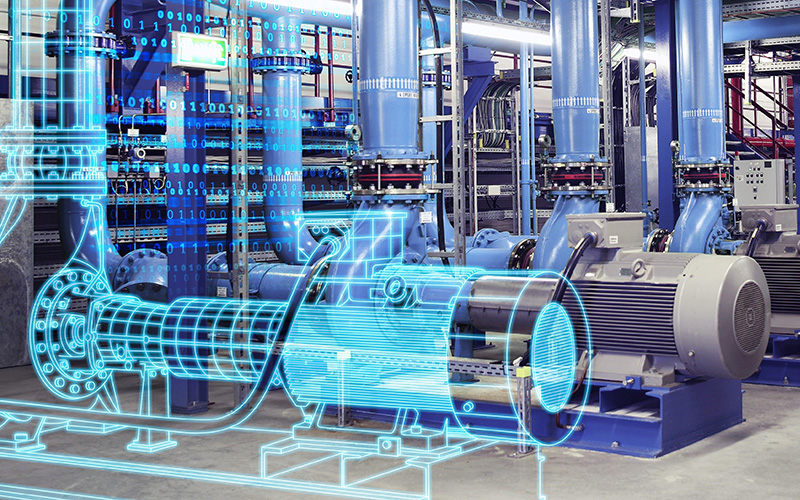

Gallery