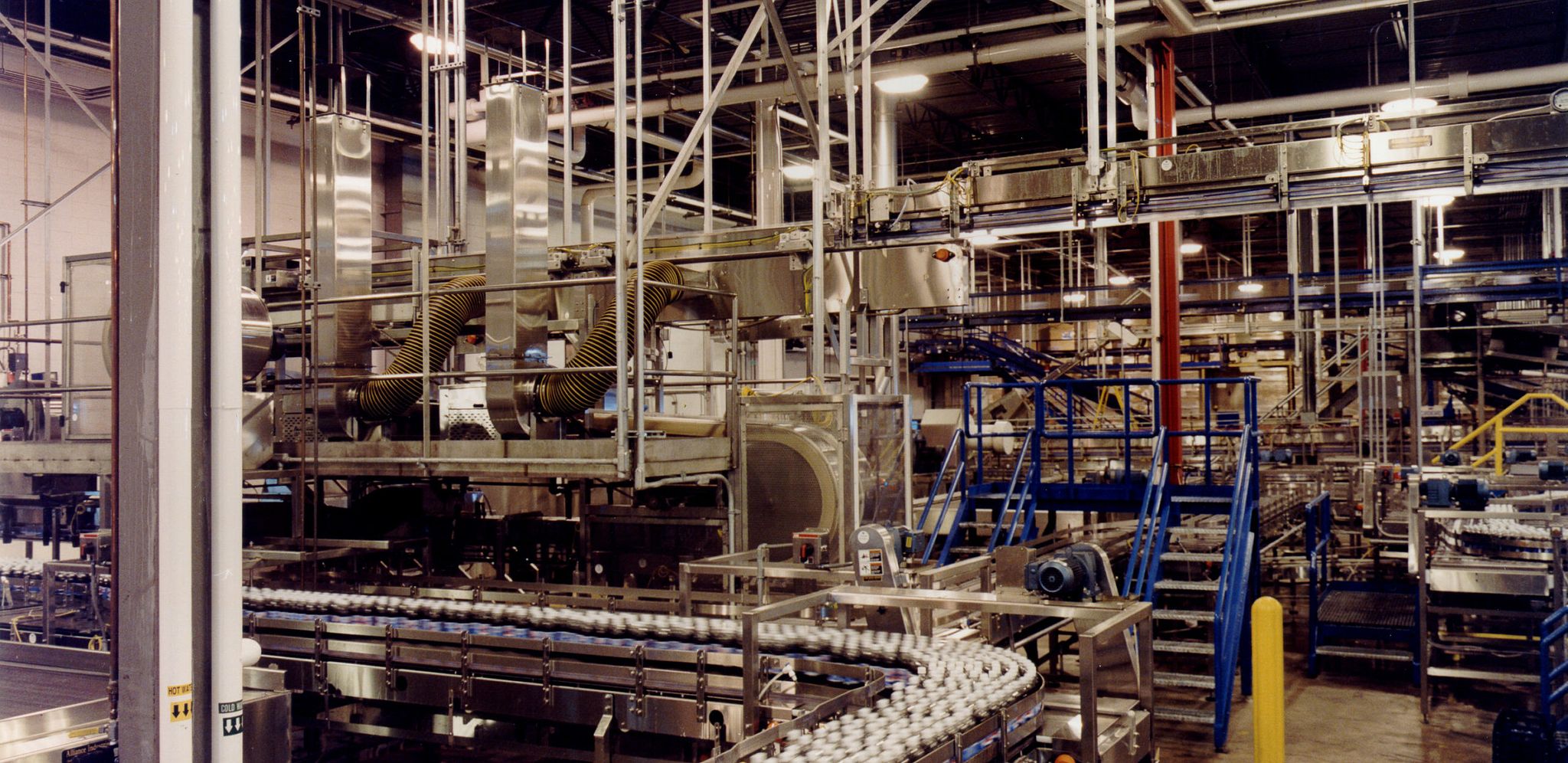

Case Study: Streamlining Maintenance Operations with TPM in FMCG Industry

Project Overview:

Niotek's Horus platform was implemented for a multinational Fast-Moving Consumer Goods (FMCG) company, focusing on Total Productive Maintenance (TPM) to increase overall equipment effectiveness and reduce downtime, ultimately boosting productivity and profitability.

Challenges:

The company sought to enhance maintenance operations, gain better visibility into equipment performance, and reduce unplanned downtime to improve overall productivity.

Solution:

Niotek collaborated closely with the maintenance and production teams, conducting a thorough analysis to customize the TPM module. The solution included tracking equipment performance, scheduling preventive maintenance, and providing real-time alerts for maintenance issues.

Implementation Highlights:

- Proactive Maintenance: The TPM module enabled proactive issue addressing, preventing unplanned downtime.

- Efficient Maintenance Management: The module improved maintenance activity scheduling, reducing downtime and increasing productivity.

- Centralized System: Horus provided a centralized system for managing and monitoring maintenance operations, facilitating data-driven decisions.

Results:

With the implementation of the TPM module, the company achieved:

- Improved Visibility: Better visibility into equipment performance, enabling proactive issue resolution.

- Efficiency Gains: Efficient maintenance scheduling and management resulted in reduced downtime and increased productivity.

- Centralized Monitoring: Horus provided real-time visibility into equipment status, maintenance schedules, and overall equipment performance.

Conclusion:

The implementation of Niotek's Horus platform with the TPM module delivered a comprehensive solution, streamlining maintenance operations for the FMCG company. The centralized system facilitated data-driven decisions, ultimately leading to increased productivity and profitability.

Gallery