Niotek Successfully Optimized on Intel Architecture

Niotek has successfully optimized its advanced Industrial IoT platform, HORUS, on Intel Architecture. HORUS, powered by AI, enhances manufacturing processes with features like hybrid architecture support, image classification, and asset failure prediction. Optimization using Intel's OpenVINO and Core Ultra processors delivers faster processing, lower latency, and high throughput. Niotek continues to innovate in IIoT and AI solutions, driving efficiency and reducing costs.

Improving manufacturing process with IIoT

The integration of internet-connected devices and sensors into industrial systems and procedures is known as the Industrial Internet of Things (IIoT). The IIoT has the potential to dramatically increase productivity and efficiency in the industrial sector by delivering real-time data and insights that can be used to streamline procedures and make wise decisions. Applying predictive maintenance is one method for using the IIoT to improve manufacturing processes. Predictive maintenance is a method that gathers information from sensors on machinery and equipment using the IIoT to determine when maintenance is required before a breakdown occurs.

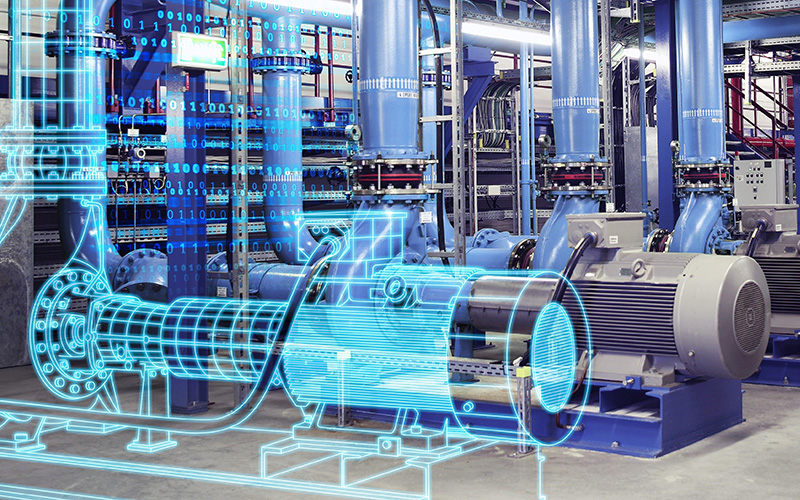

Digital Twin

Digital twin refers to a digital replica of physical assets, processes and systems that can be used for various purposes. The digital representation provides both the elements and the dynamics of how an IoT device, equipment, or machine operates and lives throughout its life cycle.