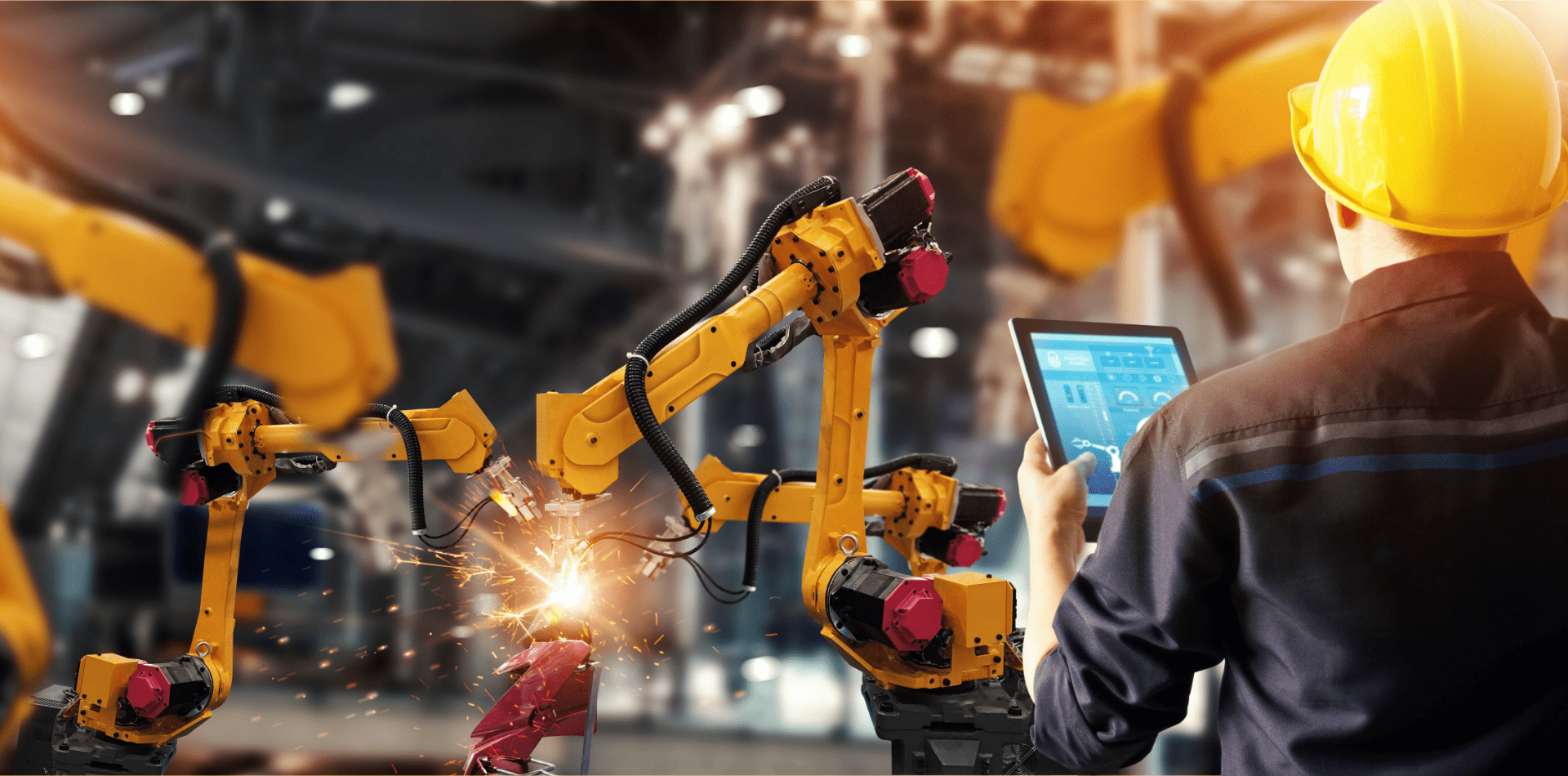

HORUS, Niotek's innovative platform, stands at the forefront of technological prowess, ushering in a new era of smart manufacturing. Rooted in the heart of Industry 4.0, HORUS is a testament to Niotek's commitment to delivering cutting-edge solutions that redefine how businesses approach quality control, production efficiency, and overall operational excellence.

At its core, HORUS is a manifestation of Niotek's dedication to addressing the critical challenges faced by industries in quality and productivity. The platform is designed to provide real-time visibility and actionable insights into the intricate workings of machines, production lines, and entire facilities. This level of visibility is crucial for businesses seeking to optimize their operations and stay ahead in a competitive landscape.

One of the key features that set HORUS apart is its utilization of Plant Digital Twin technology. This innovative approach involves creating a digital replica of physical assets, allowing for a virtual representation of the entire production process. This digital twin facilitates real-time monitoring, analysis, and simulation, enabling businesses to make informed decisions based on accurate and up-to-date data. The result is a proactive approach to production management, minimizing downtime and maximizing efficiency.

A pivotal component of HORUS is the integration of Ogat, an augmented reality (AR) and artificial intelligence (AI) sub-system. Ogat adds a layer of predictive capability to the platform, leveraging machine learning algorithms to foresee potential asset failures before they occur. This shift towards predictive maintenance is a game-changer for manufacturers, as it allows them to address issues before they impact production, ultimately reducing downtime and maintenance costs.

The application of AR within Ogat is particularly transformative. It provides on-the-spot, context-aware information to operators and maintenance personnel, enhancing their ability to troubleshoot issues and perform tasks efficiently. This not only contributes to the overall effectiveness of operations but also empowers the workforce with valuable insights and expertise.

The significance of HORUS becomes more apparent when considering the economic impact of poor-quality manufacturing. Businesses often face substantial losses due to inefficiencies, defects, and unplanned downtime. HORUS aims to be the solution to these challenges by offering a comprehensive platform that not only identifies issues but also equips businesses with the tools to proactively address them.

Studies indicate that the cost of poor-quality can lead to significant losses in gross sales volume for manufacturers, ranging from 5% to 30%. These losses directly translate to production capacity, material waste, and increased power consumption. HORUS steps in as a strategic ally, helping businesses mitigate these losses by providing actionable insights and predictive maintenance capabilities.

Furthermore, the platform's adaptability makes it suitable for various industries, from discrete manufacturing to process industries. Whether it's monitoring the efficiency of assembly lines in automotive manufacturing or optimizing chemical processes in a refinery, HORUS offers a tailored solution that aligns with the unique needs of each industry.

Niotek's journey with HORUS is not just about technology; it's about delivering practical solutions to the industry. The platform is a result of collaborative efforts from a team of technologists, manufacturing experts, and entrepreneurs. Their collective focus is on creating a tool that not only meets the current demands of the industry but also evolves with emerging technologies and challenges.

In conclusion, HORUS is more than just a platform; it's a strategic enabler for businesses venturing into the future of manufacturing. With its real-time visibility, predictive maintenance capabilities, and integration of cutting-edge technologies like AR and AI, HORUS empowers industries to overcome challenges, optimize operations, and achieve new heights of efficiency in the dynamic landscape of smart manufacturing.