Predictive Maintenance: A Game-Changer for Industrial Efficiency

Learn how advanced technologies like the Industrial Internet of Things (IIoT) and machine learning are reshaping equipment upkeep, reliability, and operational efficiency.

How IIoT is Revolutionizing Manufacturing Processes

Explore how the Industrial Internet of Things (IIoT) is transforming manufacturing processes, ushering in a new era of efficiency, precision, and data-driven decision-making

Unleashing the Power of Connectivity in Industrial Operations

Explore Niotek's Industrial Internet of Things (IIoT) solutions, leading the way in connectivity, data-driven decision-making, and operational efficiency in the era of Industry 4.0.

Improving manufacturing process with IIoT

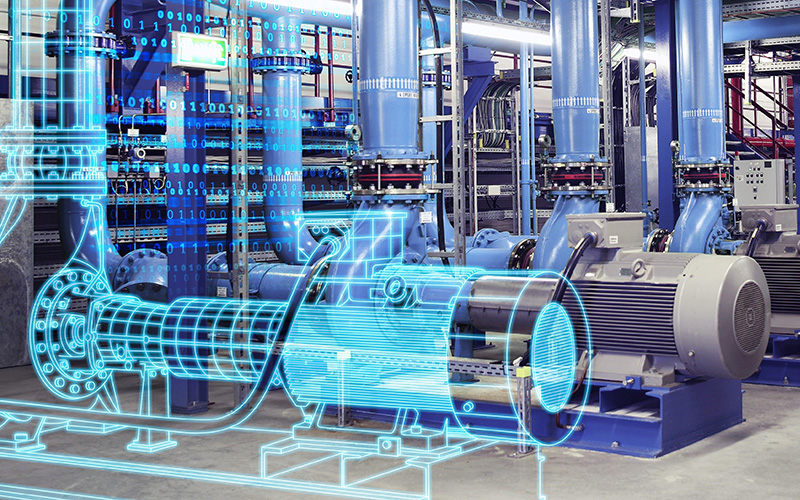

The integration of internet-connected devices and sensors into industrial systems and procedures is known as the Industrial Internet of Things (IIoT). The IIoT has the potential to dramatically increase productivity and efficiency in the industrial sector by delivering real-time data and insights that can be used to streamline procedures and make wise decisions. Applying predictive maintenance is one method for using the IIoT to improve manufacturing processes. Predictive maintenance is a method that gathers information from sensors on machinery and equipment using the IIoT to determine when maintenance is required before a breakdown occurs.

IIoT

The IIoT is part of a larger concept known as the Internet of Things (IoT). The IoT is a network of intelligent computers, devices, and objects that collect and share huge amounts of data. The collected data is sent to a central Cloud-based service where it is aggregated with other data and then shared with end users in a helpful way.

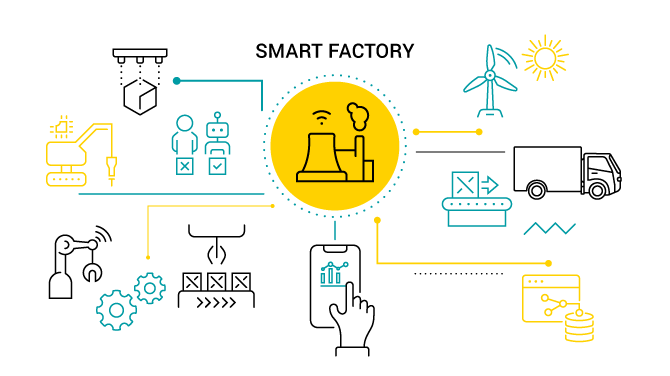

What is Smart Factory?

A Smart Factory is a fully digital factory floor that collects and shares data on a continuous basis through connected machines, gadgets, and production systems. Self-optimizing devices or the entire organization can then use the data to proactively fix faults, optimize production processes, and respond to new requests. Artificial Intelligence (AI), Big Data Analytics, Cloud Computing, and Industrial IoT (Internet of Things) are some of the technologies used in smart factories. Because all data can be delivered to a tablet or even a mobile phone and he can make adjustments remotely, a smart factory operator can watch the entire production process from the manufacturing tools and the supply chain from anywhere, including at home.